Description

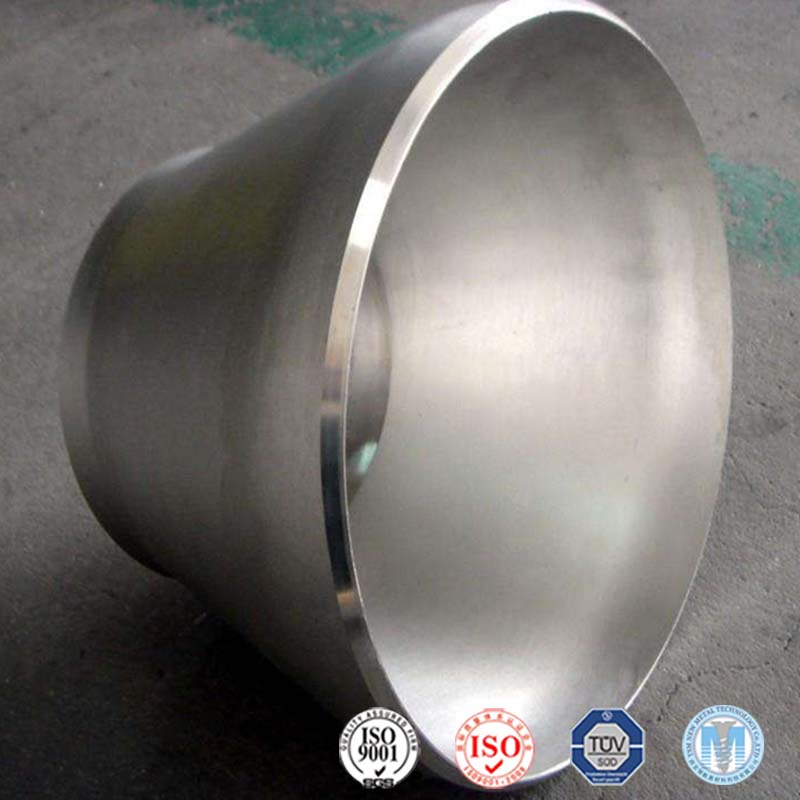

ASTM B363 Titanium Concentric Reducer

Type: NPS 1/4″ – 24″(DN15-1200) Concentric, eccentric,

Material: Gr2, Gr7, Gr12

Specifications: Outer diameter DN15-1200, NPS 1/2″-48″

Wall thickness : Sch10s-Sch160

Standard ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B

Technique: Welded, Forged, Rolled, Seamless

Surface finished: Sand blasting, Polishing, Pickling

Quality control: 100% of the X-ray detection (RT), 100% of Surface penetrant inspection (PT)

Application: Petroleum, Chemical Industry, Chloralkali, Metallurgy, Carbonization, Refrigeration, Light Industry, Salt Industry, Electric Power,etc.

Packing: Plywood Pallets/ Wooden Case Or As Per Your Specification.

Marks and stamp: As per client’s request. All products are marked by laser after they are finished

Certificate: TUV,SGS, ISO9001

Material Test Report: EN10204.3.1

Applications

Widely used in the petroleum, industry, smelting, shipbuilding,medical,cooling pipe,titanium heat pipe,Electroplating equipment ring,precision instruments aerospace field

Chemical requirements

| N | C | H | Fe | O | Al | V | Pd | Mo | Ni | Ti | |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | balance |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12-0.25 | / | / | balance |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.0-3.0 | 2.0-3.0 | / | / | / | balance |

Tensile requirements

| Grade | Tensile strength(min) | Tensile strength(min) | Yeild strength(min) | Yeild strength(min) | Elongation |

| / | Ksi | Mpa | Ksi | Mpa | % |

| Gr2 | 50 | 345 | 40 | 275 | 20 |

| Gr7 | 50 | 345 | 40 | 275 | 20 |

| Gr12 | 90 | 620 | 70 | 438 | 15 |

Titanium Pipe Fittings Features:

1) Strictly implements the technical specification of ASME B16.9, ASTM B363 etc.

2) Titanium Elbows (45D, 90D, 180D) NPS 1/4″ – 24″

3) Titanium Reducers (concentric, eccentric) NPS 1/4″ – 24″

4) Titanium Tees (equal, reducing) NPS 1/4″ – 4″

5) Titanium Stub ends NPS1/4″ – 4″

6) Titanium flange,reducer,caps,valves available.

7) Feature:Low density, high specific strength, high corrosion resistance and good thermal stability.

8) Quality and test: Strick test is indispensable, we must insure our clients’ demands.